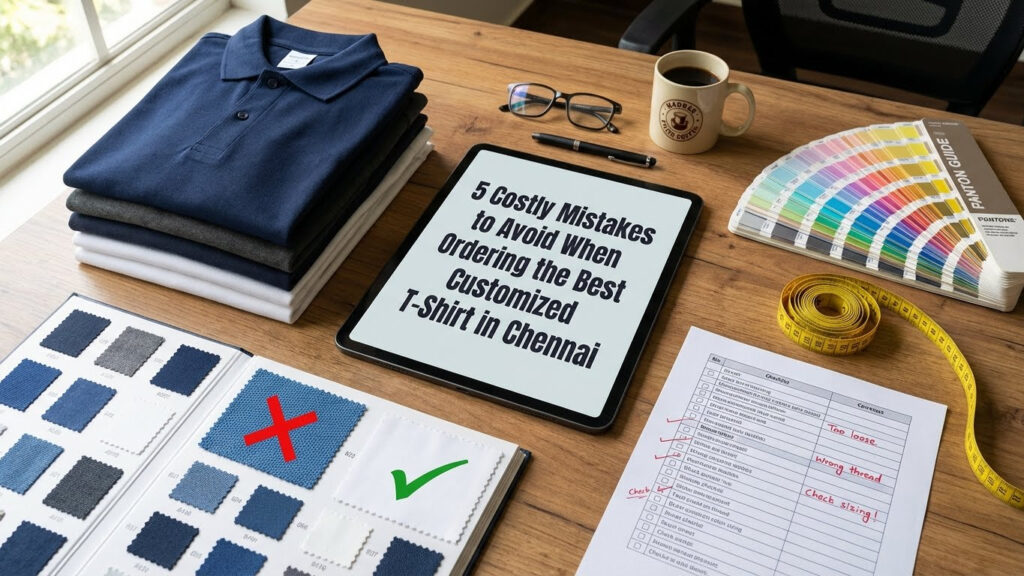

The most costly mistakes to avoid when ordering the best customized t-shirts in Chennai include skipping sample approval before bulk production (leading to expensive reprints), choosing suppliers based solely on lowest price (resulting in poor quality), providing low-resolution design files (causing blurry prints), ignoring fabric quality and GSM specifications (affecting comfort and durability), and unrealistic timeline expectations without proper planning (forcing expensive rush charges). Understanding these mistakes to avoid when ordering the best customized t-shirts in Chennai saves businesses and individuals thousands of rupees while ensuring satisfaction with final products that meet quality, timeline, and budget expectations.

Contents

- 1 Why These Mistakes Cost You More than Money

- 2 Mistake 1: Skipping Sample Approval before Bulk Production

- 3 Mistake 2: Choosing Suppliers Based Only on Lowest Price

- 4 Mistake 3: Providing Poor Quality Design Files

- 5 Mistake 4: Ignoring Fabric Quality and Specifications

- 6 Mistake 5: Unrealistic Timeline Expectations

- 7 Frequently Asked Questions

- 7.1 How much should I expect to pay for quality customized t-shirts in Chennai?

- 7.2 How long does customization typically take?

- 7.3 Can I get customized t-shirts without samples?

- 7.4 What file format should I provide for my design?

- 7.5 How do I know if I am getting quality fabric?

- 7.6 What if I need shirts urgently for an event next week?

- 7.7 Should I choose the supplier with the most promises?

- 7.8 How many shirts should I order extra for new hires and replacements?

- 7.9 Can I return customized t-shirts if I am not satisfied?

- 7.10 What should I do if I discover problems after delivery?

- 8 Conclusion: Success Through Learning

Why These Mistakes Cost You More than Money

Ordering customized t-shirts seems straightforward until something goes wrong. Then you discover that mistakes cost far more than the price difference you tried to save.

Poor quality uniforms damage your brand reputation. When employees wear shabby-looking shirts, customers notice. That negative impression lingers long after you fix the problem.

Wasted time compounds financial losses. Reordering because of mistakes means missing event deadlines or delaying product launches. Time has value that simple refunds cannot recover.

Employee morale suffers from uniform failures. Team members feel embarrassed wearing poorly made or badly designed shirts. This dissatisfaction affects productivity and workplace culture.

Relationship damage with suppliers creates future problems. Disputes over quality or specifications burn bridges with vendors. You lose access to reliable partners for future needs.

Learning from others’ expensive lessons makes sense. The mistakes to avoid when ordering the best customized t-shirts in Chennai discussed here come from real experiences. Understanding them protects your investment and ensures successful outcomes.

Print Pixels has witnessed countless customers struggle with these exact issues. We share this knowledge helping you succeed on your first order rather than learning through costly errors.

Mistake 1: Skipping Sample Approval before Bulk Production

The single most expensive mistake to avoid when ordering the best customized t-shirts in Chennai is proceeding to bulk production without physical sample approval. This oversight causes more wasted money than any other error.

Why Samples Matter So Much

Digital mock-ups look different from physical products. Colors on screens never perfectly match printed fabric. What appears vibrant digitally may look dull physically.

Print quality varies between suppliers dramatically. Two vendors using identical digital files produce noticeably different results. Only physical samples reveal actual quality.

Fabric feel cannot be judged from specifications alone. GSM numbers and material descriptions mean little until you touch actual fabric. Comfort becomes apparent only through physical handling.

Sizing inconsistencies plague the industry. Size charts provide guidelines, but actual fit varies between brands and manufacturers. Samples let you verify sizing accuracy before committing to hundreds of pieces.

The Real Cost of Skipping Samples

Consider this scenario that Print Pixels observes regularly: A company orders 200 shirts for a corporate event without samples. Upon delivery, they discover prints are smaller than expected, colors do not match brand guidelines, and fabric feels cheap. The entire order becomes unusable.

Reordering costs double the budget. You pay for defective shirts plus replacement order. Most suppliers refuse full refunds once production completes, especially for custom work.

Timeline disasters follow quality problems. Events cannot wait for replacements. You either use substandard shirts damaging your image or scramble for alternatives at premium prices.

Relationship damage with your team creates lingering resentment. Employees remember when management provided uncomfortable or unattractive uniforms. This mistake to avoid when ordering the best customized t-shirts in Chennai affects morale for months.

How to Request and Evaluate Samples Properly

Request samples using exact specifications. The sample should match your bulk order fabric, colors, print size, and placement. Generic samples showing supplier capabilities reveal nothing about your specific order.

Expect to pay for samples. Quality suppliers charge 200-500 rupees per sample piece. Many credit this amount toward bulk orders. Consider samples as insurance, not expense.

Test samples rigorously. Wear them for a full day. Wash and dry them following care instructions. Check print durability, fabric comfort, and color consistency after washing.

Involve decision-makers in sample approval. If ordering for a team, have representatives try samples. Multiple perspectives prevent oversight of issues you might miss individually.

Document sample approval in writing. Email confirmation stating “approved for bulk production” protects both parties. This documentation prevents disputes about whether samples accurately represented bulk orders.

Sample Cost vs. Bulk Failure Cost

Sample investment typically runs 500-1,500 rupees for 2-3 pieces. This small amount prevents disasters costing 50,000-200,000 rupees or more. The mathematics clearly favor sample approval as critical mistake to avoid when ordering the best customized t-shirts in Chennai.

Print Pixels always recommends sample approval regardless of customer eagerness to proceed. We have seen too many regrets from those who skipped this step.

Mistake 2: Choosing Suppliers Based Only on Lowest Price

Price-shopping makes sense until you receive what dirt-cheap pricing actually delivers. Selecting suppliers solely on lowest quotes ranks among the most common mistakes to avoid when ordering the best customized t-shirts in Chennai.

Understanding the Price-Quality Connection

Customization has floor costs below which quality becomes impossible. Quality fabric, skilled printing, proper equipment, and fair labour have minimum costs. Prices significantly below market rates mean corners are being cut somewhere.

Cheap fabric feels and looks cheap. Thin, rough material with poor drape creates unprofessional appearance. These shirts often become semi-transparent when stretched, embarrassing for wearers.

Inferior inks fade rapidly. Bargain suppliers use cheap inks that crack, peel, or wash out within 10-15 washes. Your beautiful design becomes a faded mess quickly.

Rushed production causes quality issues. Suppliers offering rock-bottom prices often overextend capacity. They rush through orders creating misalignment, incomplete coverage, and poor curing.

The Hidden Costs of Cheap Suppliers

Replacement frequency doubles or triples. Cheap shirts typically last 3-6 months versus 12-18 months for quality alternatives. You spend more replacing frequently than investing properly initially.

Brand damage from shoddy appearance costs more than money. Customers judge your business by employee appearance. Cheap-looking uniforms suggest a cheap-quality business.

Unreliable delivery creates operational chaos. Discount suppliers often miss deadlines, leaving you scrambling. This unreliability disrupts events, launches, and business operations.

Poor customer service leaves you stuck. Budget suppliers rarely provide design assistance, size exchanges, or problem resolution. You are alone when issues arise.

Identifying Fair Pricing

Market rates for quality customized t-shirts in Chennai follow predictable ranges. Basic screen-printed shirts with decent fabric cost 180-280 rupees per piece for orders of 50-100 units. Premium options range 350-600 rupees.

Request itemized quotes from multiple suppliers. Compare fabric specifications, printing methods, and included services. Low total price may hide cheap fabric or inadequate printing while competitors offering better value appear more expensive.

Investigate unusually low prices. If most quotes cluster around 250 rupees while one offers 150 rupees, question what differs. Often the cheap option uses inferior materials or inexperienced staff.

This mistake to avoid when ordering the best customized t-shirts in Chennai teaches that value, not just price, determines smart purchasing. Print Pixels prices competitively while maintaining quality standards that cheap suppliers cannot match.

When Price Should Be the Deciding Factor

Price legitimately determines choice only after qualifying suppliers on quality, reliability, and service. Compare prices among vendors meeting your quality standards. Then choosing lowest price makes sense.

Mistake 3: Providing Poor Quality Design Files

Design file quality directly affects print quality. Supplying inadequate files ranks among the most frustrating mistakes to avoid when ordering the best customized t-shirts in Chennai for both customers and suppliers.

Understanding File Format Requirements

Vector files offer unlimited scalability. Formats like AI, EPS, or PDF containing vector artwork scale infinitely without quality loss. These files work perfectly for screen printing and vinyl cutting.

Raster files require high resolution. PNG or JPG files need minimum 300 DPI at print size. Lower resolution creates pixelated, blurry prints that look unprofessional.

File type affects printing method. Different techniques prefer specific formats. Screen printing works best with vector files. Digital printing accepts high-resolution raster files. Embroidery requires specialized digitized files.

Common File Quality Problems

Social media downloads lack adequate resolution. Images pulled from Facebook, Instagram, or websites rarely exceed 72-150 DPI. These look fine on screens but print terribly.

Stretched or enlarged images lose clarity. Taking a small logo and expanding it for large chest print creates blurry results. Resolution cannot be added after the fact.

Incorrect color modes cause color mismatches. RGB files designed for screens produce different colors when converted to CMYK for printing. Unexpected color shifts disappoint customers.

Compressed files lose detail. Repeatedly saved JPG files degrade through compression artifacts. These artifacts become visible when printed large.

The Cost of Bad Design Files

Reprinting due to file quality issues wastes money completely. Once you approve and pay for prints from poor files, suppliers bear no responsibility. You pay twice for the same design.

Rushed file fixes compromise results. When suppliers try optimizing inadequate files, results rarely match original vision. The compromise often disappoints despite best efforts.

Delayed production affects timelines. Discovering file problems after production starts requires stopping, fixing files, and restarting. This delay jeopardizes deadlines.

This mistake to avoid when ordering the best customized t-shirts in Chennai frustrates because it is entirely preventable with proper preparation.

Preparing Files Correctly

Source files from original designers when possible. Contact whoever created your logo requesting proper print files. Explain you need vector formats or 300+ DPI raster files at actual print size.

Work with design professionals if creating new artwork. Explain your printing plans so designers prepare appropriate files. Investing 1,000-3,000 rupees in professional design prevents expensive printing problems.

Request file evaluation before production. Print Pixels and other quality suppliers review files before printing, flagging potential problems. This preview catches issues while fixes remain easy.

Provide multiple file formats. Send both vector and high-resolution raster versions. This redundancy ensures suppliers have workable files regardless of printing method.

Include Pantone color codes for exact color matching. Specific color references prevent misunderstandings about desired shades. Verbal descriptions like “bright red” mean different things to different people.

Mistake 4: Ignoring Fabric Quality and Specifications

Fabric quality fundamentally determines t-shirt performance. Neglecting fabric selection represents a critical mistake to avoid when ordering the best customized t-shirts in Chennai affecting comfort, durability, and professional appearance.

Why Fabric Quality Matters

Comfort affects whether employees actually wear uniforms. Scratchy, stiff, or hot fabrics get left in closets. Comfortable fabrics get worn willingly and regularly.

Durability determines replacement frequency. Quality fabrics maintain appearance through 50-100 washes. Cheap materials pill, fade, and deteriorate within 20-30 washes.

Professional appearance influences brand perception. Quality fabric drapes nicely and maintains shape. Cheap fabric looks obviously cheap, reflecting poorly on your brand.

Print adhesion depends on fabric surface. Some fabrics accept prints beautifully while others cause premature fading or poor coverage. Fabric affects print longevity significantly.

Understanding Fabric Specifications

GSM indicates fabric weight and thickness. Higher GSM generally means thicker, more substantial fabric. The 180-200 GSM range suits most applications balancing quality and comfort.

Fiber content affects properties dramatically. 100% cotton breathes well but wrinkles easily. Poly-cotton blends resist wrinkles and dry faster. Performance fabrics wick moisture but feel synthetic.

Weave type influences feel and durability. Jersey knit feels soft and stretchy. Tighter weaves resist wear better. Slub cotton has textured appearance but uneven printing surface.

The Cost of Fabric Mistakes

Uncomfortable fabrics create resistance. When Print Pixels customers choose cheap fabric despite recommendations, employees complain immediately. Morale suffers and uniform adoption fails.

Rapid deterioration requires early replacement. Budget fabric often needs replacing within 6 months. Quality fabric lasts 12-18 months. False economy becomes apparent quickly.

Unsuitable fabric for printing method causes problems. Digital printing requires cotton-dominant blends. Sublimation needs polyester. Wrong fabric choice limits printing options or produces poor results.

Choosing Appropriate Fabric

Match fabric to purpose and environment. Office environments suit comfortable cotton or poly-cotton. Field work benefits from durable blends. Chennai’s climate generally favors breathable materials.

Specify fabric requirements clearly. Provide GSM range, fiber content preferences, and any special requirements. Vague orders like “good quality fabric” mean different things to different suppliers.

Feel fabric samples before large orders. Physical touch reveals softness, weight, and quality that specifications cannot fully convey. This sensory evaluation prevents surprises.

This mistake to avoid when ordering the best customized t-shirts in Chennai seems technical but profoundly affects satisfaction with finished products.

Fabric Selection Questions to Ask

What is the exact GSM? Vague answers like “good weight” are insufficient. Demand specific numbers.

What is fiber composition percentage? 65% polyester / 35% cotton differs significantly from 50/50 blends.

What brand or manufacturer produces the fabric? Established fabric manufacturers provide consistency. Unknown sources vary unpredictably.

Can I see and feel a fabric sample? If suppliers refuse or claim samples are unavailable, consider this a red flag.

Mistake 5: Unrealistic Timeline Expectations

Rushing customization without understanding production requirements creates expensive problems. Unrealistic timeline expectations represent a frustrating mistake to avoid when ordering the best customized t-shirts in Chennai causing stress and additional costs.

Understanding Standard Production Timelines

Screen printing requires 7-14 business days including design finalization, screen preparation, printing, curing, quality checking, and packing. This timeframe applies to normal business periods with standard orders.

Digital printing completes faster at 3-5 business days due to eliminated setup time. However, large digital orders may take longer due to printing capacity limitations.

Embroidery timelines depend on complexity and quantity. Simple logos on 50 shirts might complete in 7 days. Complex designs on 200+ shirts require 14-21 days.

Design creation adds time before production starts. Custom design work takes 2-5 days depending on complexity and revision rounds. Using existing artwork eliminates this phase.

Busy seasons extend all timelines. December-January, March-May, and August-October create capacity constraints across Chennai’s customization industry. During peak periods, add 3-7 days to standard timelines.

The Cost of Poor Planning

Rush charges add 25-50% to standard pricing. Suppliers must prioritize your order over others, often working overtime. These real costs get passed to customers demanding rush service.

Quality compromises emerge from extreme rushing. Adequate drying time, proper quality checking, and careful production require minimum time. Rushing beyond reasonable limits increases defect risks.

Impossible deadlines cause complete failure. No supplier can create additional time. When customers demand physically impossible timelines, disappointment becomes inevitable.

Alternative supplier desperation leads to poor choices. Panicking about tight deadlines, customers accept any supplier promising quick delivery. These rushed decisions often end badly.

Planning Realistic Timelines

Add buffer time to supplier quotes. If suppliers quote 10 days, plan for 12-14 days. Unexpected delays happen. Buffer time prevents disasters when minor delays occur.

Account for your own decision time. Approving designs, reviewing samples, and making payments takes time. Include these steps in overall timeline calculations.

Consider shipping and distribution time. Local Chennai pickup may add one day. Shipping to other cities adds 2-5 days. Final distribution to team members needs scheduling.

This mistake to avoid when ordering the best customized t-shirts in Chennai causes more stress than others but remains entirely preventable through proper planning.

Rush Order Realities

True rush service (24-48 hours) is rarely possible. Despite aggressive promises from some suppliers, quality work requires minimum time. Be skeptical of impossible timeline promises.

Assess true urgency honestly. Many “urgent” orders actually have flexibility. Events have fixed dates known months in advance. Real planning eliminates most emergency situations.

Build relationships with reliable suppliers like Print Pixels for genuine emergencies. Suppliers knowing and trusting you may accommodate occasional legitimate rush needs. Strangers demanding rush orders receive lowest priority.

When to Start the Ordering Process

Corporate events: Begin orders 6-8 weeks before event dates. This allows design development, sample approval, production, and comfortable buffer time.

School functions: Start 8-10 weeks ahead. School orders often involve committee approvals and payment collection creating additional timeline requirements.

Sports teams: Allow 6-8 weeks for jersey orders. Sizing variations across team members and potential exchange needs require extra time.

Family events: Start 4-6 weeks prior. Smaller orders complete faster, but personal schedules for approvals and pickups need consideration.

Retail merchandise: Plan 8-12 weeks for initial inventory. Testing designs, building inventory levels, and quality checking require generous timelines.

Learning From Others’ Mistakes

The mistakes to avoid when ordering the best customized t-shirts in Chennai discussed here derive from real customer experiences. Every point represents actual problems Print Pixels and other suppliers encounter regularly.

Smart buyers learn from others’ expensive lessons rather than repeating them. The collective experience shared here saves you money, time, and frustration.

Prevention Checklist

Before placing your order, verify you have:

- Requested and approved physical samples matching exact specifications

- Compared multiple suppliers on quality, not just price

- Provided professional-quality design files appropriate for your chosen printing method

- Specified fabric requirements clearly and felt samples

- Planned realistic timelines with adequate buffer

- Established clear communication and documentation with your supplier

- Understood all costs including potential additional charges

- Confirmed supplier credentials, references, and capabilities

- Read and agreed to terms regarding defects, exchanges, and refunds

- Protected yourself through written agreements and order confirmations

Working With Print Pixels

Print Pixels built its reputation helping customers avoid these common pitfalls. Our process includes:

Mandatory sample approval for orders over 50 pieces. We refuse bulk production without physical sample confirmation preventing costly mistakes.

Transparent pricing with detailed itemization. You understand exactly what you are paying for. No surprises, no hidden charges.

Design file review and optimization. Our team examines files before production, flagging potential problems while fixes remain easy.

Fabric specification guidance. We help you select appropriate materials for your specific needs and budget.

Realistic timeline communication. We provide honest production schedules, not impossible promises. Better to under-promise and over-deliver.

Written order confirmations. Every order receives detailed written confirmation specifying all terms, timelines, and specifications.

Quality guarantees with clear defect policies. You know in advance how we handle quality issues should they arise.

Frequently Asked Questions

How much should I expect to pay for quality customized t-shirts in Chennai?

Quality customized t-shirts in Chennai cost 180-280 rupees per piece for basic screen printing with decent fabric for orders of 50-100 units. Premium fabrics and printing methods range 350-600 rupees per piece. Prices below 150 rupees typically indicate compromised quality. The mistakes to avoid when ordering the best customized t-shirts in Chennai include choosing based solely on lowest price, as extreme budget options rarely meet expectations. Always compare value, not just cost.

How long does customization typically take?

Standard screen printing requires 7-14 business days from design approval to delivery. Digital printing completes in 3-5 days. Embroidery takes 7-14 days depending on complexity. Busy seasons add 3-7 days to these timelines. Rush service costs 25-50% extra and completes in 3-5 days. Planning ahead avoids rush charges and stress. One of the key mistakes to avoid when ordering the best customized t-shirts in Chennai is unrealistic timeline expectations without proper planning.

Can I get customized t-shirts without samples?

While possible, proceeding without samples is the most costly mistake to avoid when ordering the best customized t-shirts in Chennai. Samples costing 200-500 rupees each prevent disasters potentially costing 50,000-200,000 rupees in unusable bulk orders. Quality suppliers like Print Pixels strongly recommend samples for any order exceeding 25-30 pieces. This small investment protects your much larger bulk order investment.

What file format should I provide for my design?

Vector formats (AI, EPS, PDF) work best for screen printing and vinyl cutting. High-resolution PNG or JPG files at 300+ DPI suit digital printing. Embroidery requires specialized formats but suppliers convert from standard files. Providing poor quality files is a major mistake to avoid when ordering the best customized t-shirts in Chennai. Work with professional designers or request file review from Print Pixels before production begins.

How do I know if I am getting quality fabric?

Specify GSM (180-200 recommended for most uses) and fiber content (65% polyester/35% cotton blends work well). Request physical fabric samples before bulk orders. Quality fabric feels substantial, not thin or flimsy. It should have even texture and good color depth. Avoiding fabric quality mistakes is crucial among mistakes to avoid when ordering the best customized t-shirts in Chennai. Reputable suppliers clearly specify fabric details rather than giving vague “good quality” assurances.

What if I need shirts urgently for an event next week?

Rush orders completing in 3-5 days cost 25-50% extra. Communicate urgently with suppliers like Print Pixels who may accommodate tight timelines for existing customers. However, some timelines are physically impossible regardless of price. True quality requires minimum time. Better to explain your timeline honestly upfront. One of the costliest mistakes to avoid when ordering the best customized t-shirts in Chennai is assuming any deadline can be met with enough money.

Should I choose the supplier with the most promises?

Be cautious of suppliers promising everything: lowest prices, impossible timelines, perfect quality, unlimited revisions, and no restrictions. Realistic suppliers set appropriate expectations. Overpromising followed by underdelivering is common. Choose suppliers with honest communication over those making impressive claims. Print Pixels succeeds through transparency and realistic expectations, not unrealistic promises.

How many shirts should I order extra for new hires and replacements?

Order 10-15% extra in common sizes. For 100 shirts, order 110-115 pieces with extras in medium, large, and extra-large sizes. This buffer handles new employees, size exchanges, and replacement for damaged items. The small additional investment prevents expensive small reorders later. Smart planning helps avoid mistakes to avoid when ordering the best customized t-shirts in Chennai related to inadequate quantities.

Can I return customized t-shirts if I am not satisfied?

Custom orders are typically non-returnable except for quality defects or supplier errors. This makes sample approval critical. Once you approve samples and production proceeds to your specifications, you own the shirts regardless of satisfaction. Legitimate defects should be addressed per supplier policies. Understanding this emphasizes why preventing mistakes to avoid when ordering the best customized t-shirts in Chennai matters so much.

What should I do if I discover problems after delivery?

Document issues immediately with clear photographs. Contact your supplier within 24-48 hours. Explain problems specifically referencing order specifications and approved samples. Reputable suppliers like Print Pixels work to resolve legitimate quality issues. However, subjective preferences about approved designs rarely qualify for remedies. Prevention through proper samples and specifications beats problem-solving after the fact.

Conclusion: Success Through Learning

The mistakes to avoid when ordering the best customized t-shirts in Chennai discussed here represent real problems causing real financial losses. Understanding them protects your investment and ensures satisfaction.

Sample approval prevents quality disasters. This single step eliminates the most expensive failures in customization projects. Never skip samples for significant orders.

Value matters more than lowest price. Quality suppliers deliver better long-term value than budget alternatives. Cheap often costs more through replacements and problems.

Professional design files ensure quality printing. Invest in proper file preparation avoiding the frustration and expense of reprinting due to file quality issues.

Fabric quality determines comfort and durability. Specify requirements clearly and verify actual fabric before bulk orders. Happy wearers make successful uniform programs.

Realistic planning eliminates rush charges and stress. Start early, build buffer time, and work with honest suppliers providing achievable timelines.

Print Pixels built our business helping customers succeed through transparent processes, quality focus, and honest communication. We have seen every mistake discussed here, often multiple times. Learning from this collective experience positions you for success on your first order.

Protect your investment by avoiding these common pitfalls. The knowledge shared here represents thousands of rupees saved and countless headaches prevented. Use it wisely for your customization success.

To avoid mistakes when ordering the best customized t-shirts click here